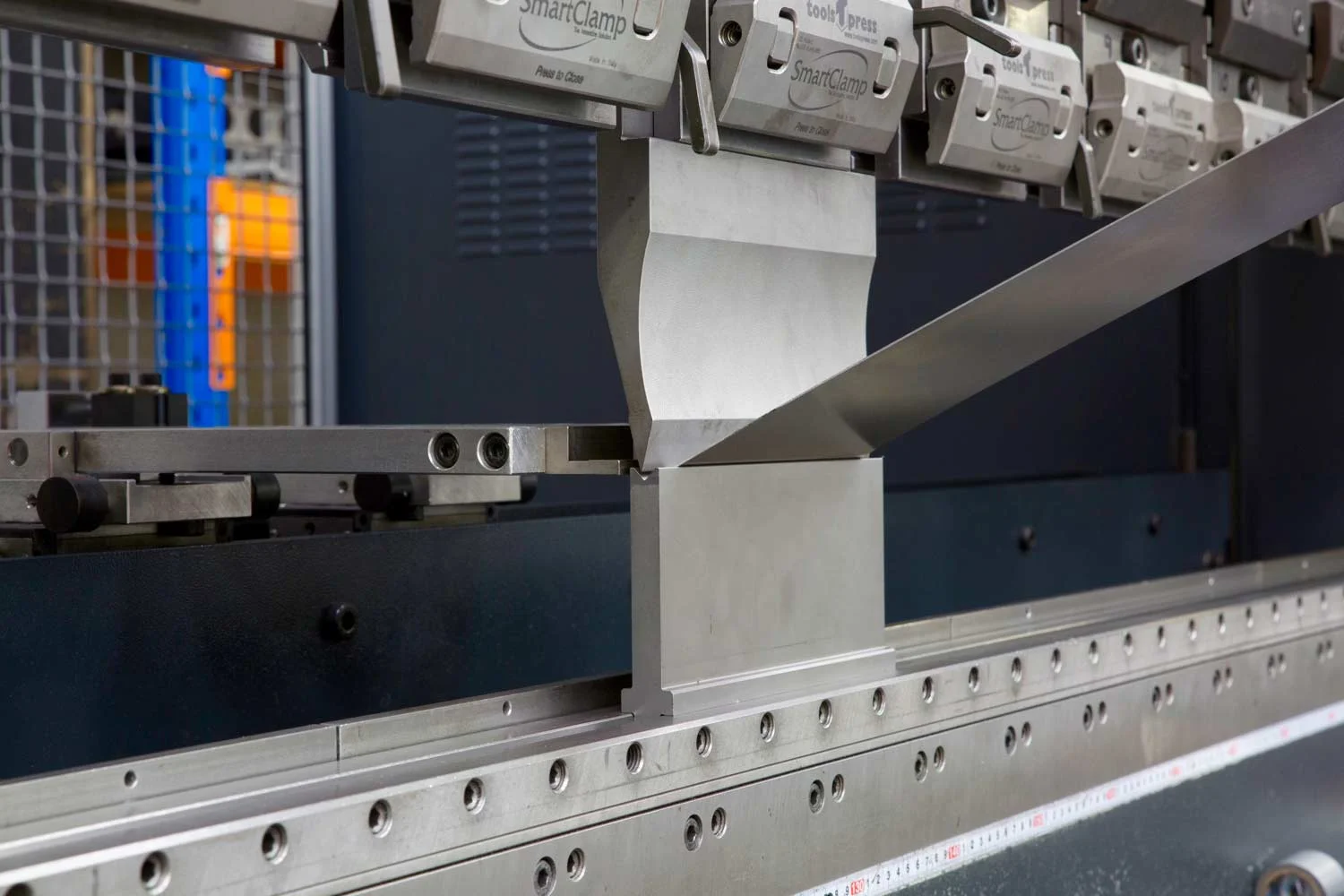

Skilled designers like our Jacek Laskowski can start drafting new sheetmetal components directly into Computer Aided Design (CAD) software like SolidWorks, but more often the process begins on a work bench amidst the other parts of the assembly, older versions of the product or even handmade mockups and paper sketches.

We love to receive CAD drawings from you whenever you have them (and customers who are product designers always do!) but either way we take time upfront to understand your product and tweak its design for better looks, strength, functionality and greater material and labour efficiency during manufacture. Final CAD design files are naturally yours to keep.

Your physical prototypes get made as soon as we're happy with the design, we inspect and scrutinise the finished product to your complete satisfaction. If somethings's not right, we make it right.

On some projects you'll need to submit your new product to third-party testing labs to determine such things as the resilience of its coatings and finish, its IP Rating, vibration and shock resistance and so on. We're glad to handle the delivery and retrieval of the prototype from these labs, as well as interface directly with the testers on any technical matters they require.

Once you're thrilled with your new product, we send it to full production.

Contact Us on 03 9720 4834

Our Services

Fastener Inserting

Power Coating, Zinc Plating and Surface Finishing

Quality Assured Assembly

Packaging and Delivery