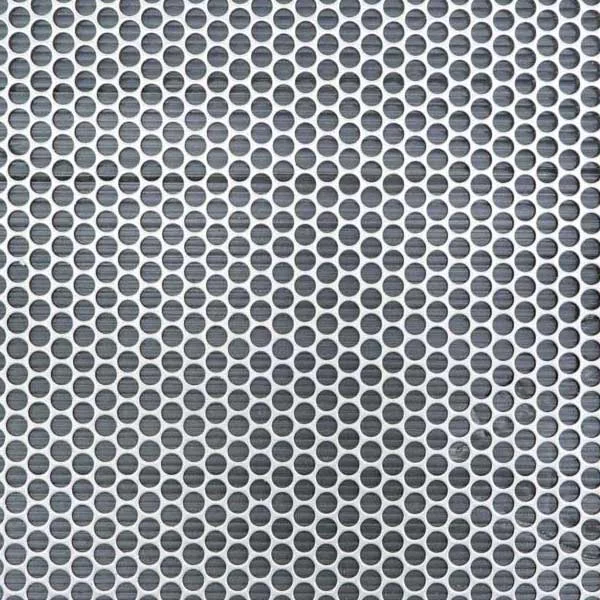

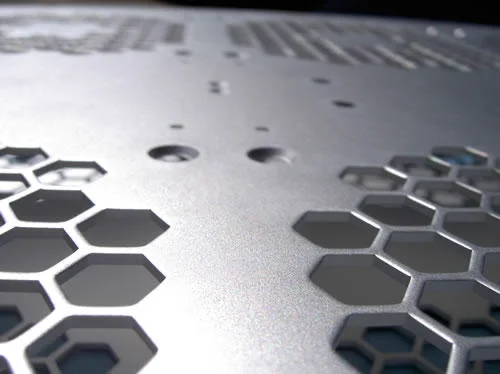

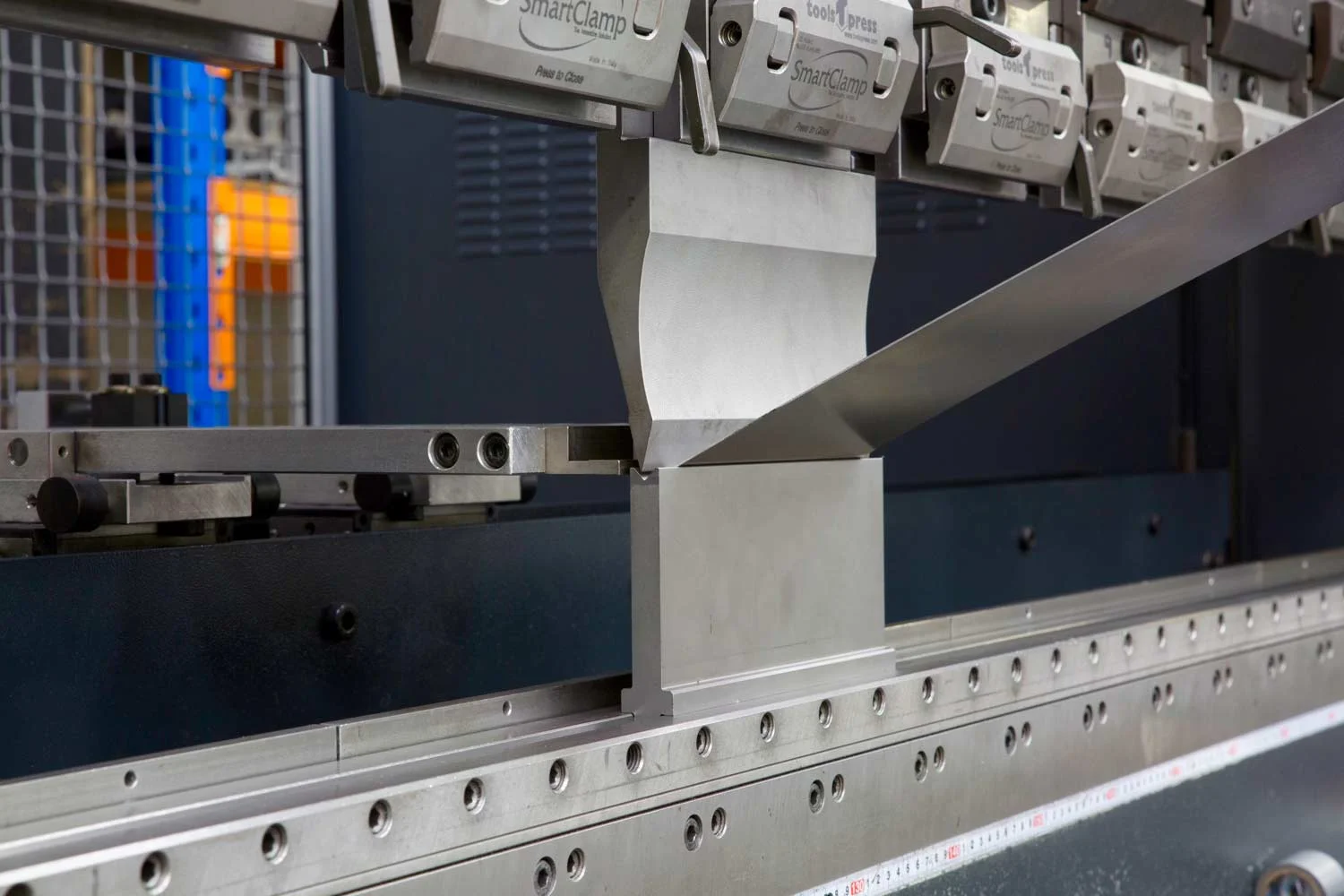

Even ultra-modern punch presses or laser cutting machines leave small abrasive burrs along the edges and holes of newly punched sheet metal parts.

If not removed these can give a rough, cheap-looking surface feel to your finished product and cause paints and coatings to chip away along these edges.

Removing burrs (deburring or linishing) can be done manually but is fastest and most consistent when using automatic surface deburrers like our Timesaver Series 1200.

Contact Us on 03 9720 4834

Our Services

Fastener Inserting

Power Coating, Zinc Plating and Surface Finishing

Quality Assured Assembly

Packaging and Delivery